HEMCO

Belt Drive Exhaust Blower for 72" Canopy Hoods

- Part Number:

- HMC-51731

- Lead Time:

- 2-4 weeks

- Shipping:

- FREE SHIPPING on most orders over $50*

- Quantity:

- each

- Color:

- gray

- Material:

- epoxy coated steel

- Country of Origin:

- Made in the USA

Bulk discount rates

Automatically save when you buy in bulk.

| Buy 6 - 11 | and get 10% off |

| Buy 12 or above | and get 15% off |

Description

HEMCO 51731 Belt Drive Exhaust Blower for 72" Canopy Hoods

A complete line of belt drive exhaust blowers that are chemical resistant and available in standard and explosion-proof models. HEMCO blowers are designed to operate effectively and efficiently to remove noxious and hazardous fumes. Standard 115V 60Hz & International Electrical Configuration of 220V 50Hz AC available.

Features:

- Standard (STD) belt drive steel blower and impeller wheel are epoxy coated for superior chemical resistance.

- Explosion-proof blowers (EXP) have epoxy coated, non-sparking aluminum impeller wheel.

- V-belt drive and adjustable pulleys permit field balancing.

- Seven discharge positions to suit installation.

- Weather housing is furnished.

- Motor has thermal overload protection.

- Specify: 115 V single phase, 230 V single phase, 230/460 V three phase or 208 V (consult factory.)

Specifications:

- Product Type: Belt Drive Exhaust Blower

- Manufacturer: HEMCO

- CFM: 1506

- HP: 1/2

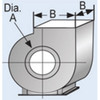

- Inlet Diameter: 11-7/8"

- Outlet Size: 13-3/8" x 8-1/4"

- Voltage/Hertz: 115V, 60Hz, 1 phase

- Color: Gray

- Material: Epoxy Coated Steel

- Country of Origin: USA

- Product Length (in) : 20

- Product Width/Dia (in) : 20

- Product Height (in) : 20

- Package Length (in) : 30

- Package Width (in) : 30

- Package Depth (in) : 30

- Shipping Weight (lbs) : 175

Blower Recommendations:

Blowers should be mounted on the roof in-order that the ducting leading to the blower inlet is under negative static pressure. If exhaust blowers are mounted inside the building, all ducting connected to the blower outlet will be under positive static pressure, if a leak were to develop in the section of the duct inside the building, toxic and or hazardous fumes could be forced out of the ductwork and into that area of the building.

To achieve the lowest practical noise level in the exhaust system, we suggest that the following measurements be used when there is no conflict with other specifications of the system: (a) Use vibration isolators or mounting blower exhaust assembly. (b) Install a blower fan that will deliver the correct CFM and static pressure with the lowest practical impeller wheel RPM. If possible, use a duct size large enough to keep duct velocity under 1800 FPM velocity. (c) Use a flexible connection at the fan inlet to isolate mechanical transmission of noise from the ducting between the hood and the exhaust blower. (d) Exhaust blower system should be designed with the fewest possible elbows or other fittings. Use radius type elbows & avoid using square elbows. Use gradual tapered transitions where necessary, & avoid abrupt changes in configuration or cross sectional area.

When ordering an exhaust blower, specify the orientation of discharge desired. Vertical up blast discharge is the most common and will be supplied unless otherwise specified.

All fans are shipped with clockwise rotation when viewed from the motor end of the assembly.