Safety Cabinet Regulations

|

|

||||||||||||||

|

||||||||||||||

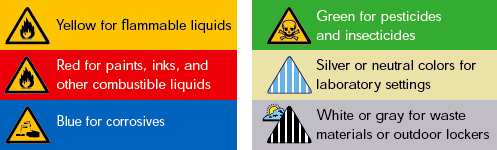

Important Considerations When Selecting a Safety CabinetSafety cabinets come in a variety of ratings colors sizes shapes and door arrangements. Beyond choosing a cabinet that meets the requirements of NFPA OSHA and carries an FM approval other factors must also be considered. Chemical Characteristics - It is important to identify and inventory all chemicals to be stored. A review of the Material Safety Data Sheet (MSDS) will determine characteristics and recommended storage practices. To avoid generating toxic explosions and to prevent fires it is critical to segregate incompatible chemicals. One factor in choosing a cabinet is how the chemical relates to the construction material of the cabinet itself. For example for non-flammable acids and corrosive liquids the construction material should be polyethylene or wood laminate. However for less aggressive corrosive liquids that exhibit flammable characteristics a chemically resistant steel cabinet with polyethylene lined shelves is recommended. Cabinets constructed of steel are suitable for flammable liquids and choosing the correct color helps organize and segregate different types of liquids. While regulatory codes do not mandate the specific color industry has customarily observed certain colors for defined liquids (see below). Regulatory and Safety Considerations - As covered earlier construction criteria must conform to specifications set forth by NFPA and OSHA. In some areas of the country where either the International Fire Code (IFC) or NFPA 1 the Uniform Fire Code is followed it is further required that the doors of a flammable liquid cabinet shall be well fitted and self-closing.* Safety cabinets come in single or two door closure styles: manual or self-closing. Economical manual close doors permit doors to open a full 180 degrees and require the user to physically shut the doors. Self-close self-indexing doors incorporate a mechanism that automatically shuts doors upon release. Fusible links hold the doors open during use but if inadvertently left open will melt at 165°F (74°C) in the event of a fire to automatically close the doors. Whereas self-closing doors are required in states that adopt a specific fire code it is recommended that local jurisdictions always be contacted for specific requirements. Self-closing doors ensure closure by taking away the &"human element"; of potentially forgetting to shut the doors. It is often therefore considered the preferred door choice for a good overall safety program. Additionally self-close mechanisms that are concealed within the top wall of the cabinet are an added benefit maximizing available storage space. Whether manual or self-closing a self-latching door and handle is critical as it does not require the user to manually rotate a handle to ensure the mandatory three-point latch is properly engaged. A stainless steel bullet-type latching system offers positive closure and optimum longevity with increased heat resistance. All Justrite cabinets have a 3-pt. stainless steel bullet self-latching system meet OSHA and NFPA and most are FM approved. |

||||||||||||||

Understanding Safety Regulations

If the chemical being stored is flammable or combustible OSHA 1910.106 applies. Though states differ your state and local codes are likely based on either the National Fire Protection Association Code (NFPA 30) and/or the Uniform Fire Code (UFC 79). Section 4.3 of the 2000 edition of NFPA covers the design construction and capacity of storage cabinets. In addition to passing a fire test NFPA further requires specific cabinet construction. Whereas both metal and wood construction are acceptable the most popular choice in industry is metal. One notable distinction in the Uniform Fire Code 7902.5.9.3.2 is the requirement that all flammable and combustible liquid storage cabinets shall be self-closing. In addition to assuring that cabinets meet applicable codes it's important to look for safety storage cabinets which carry independent third party certification such as Factory Mutual (FM Approved) or Underwriter's Laboratories (UL Listed). Codes vary internationally. For example in some applications in Canada the Canadian National Fire Code may require cabinets to carry a ULC listing which requires a more stringent fire test than UL Listing. While NFPA does not mandate requirements for the storage of nonflammable acids and corrosives these chemicals should be properly stored for maximum safety. A wide variety of code compliant cabinets are available in sizes ranging from 4-gallons (15 liters) to 120-gallons (454 liters). Smaller cabinets allow solvents to be stored at work site locations saving costly trips to a central storage room. Under counter countertop wall mount and piggyback / stackable cabinets add to safe storage even when space is at a premium. For high capacity storage including storage of 55-gallon drums larger sized cabinets designed specifically to house 30-gallon (114 liter) or 55-gallon (208 liter) drums are available. It's important to note that OSHA Code 29 CFR 1910.106 states that not more than 60-gallons may be Class I and II liquids. Custom sized cabinets are also available for unique requirements. |

||||||||||||||

Choosing a Safety Cabinet ColorCabinets are available in a variety of colors to help designate content. Steel flammable cabinets come in different colors to organize and segregate different types of liquids. While regulatory codes do not mandate the specific color industry has customarily observed certain colors for defined liquids:

|

||||||||||||||

State-Specific Regulations on Self-Closing CabinetsSelf-closing safety cabinets are required by certain states and certain districts within states that follow an adopted Fire Code (such as the International Fire Code (IFC) or NFPA 1 Uniform Fire Code.) The following states have at least some areas that are required to purchase safety cabinets with self closing doors.

|

||||||||||||||

**This list is not all inclusive. Contact your local jurisdiction to find out your local requirements.

One of the leading causes of industrial fires is the improper storage and handling of flammable liquids. It is important to identify and inventory all chemicals in your workplace. Review the MSDS (Material Safety Data Sheet) for each chemical to determine characteristics and recommended storage practices. To avoid generating toxic gases and to prevent fires and explosions it is important to segregate incompatible chemicals. Some local regulations require positive-pressure ventilation. Justrite cabinets offer fire-baffle protected vents to connect to these systems.

One of the leading causes of industrial fires is the improper storage and handling of flammable liquids. It is important to identify and inventory all chemicals in your workplace. Review the MSDS (Material Safety Data Sheet) for each chemical to determine characteristics and recommended storage practices. To avoid generating toxic gases and to prevent fires and explosions it is important to segregate incompatible chemicals. Some local regulations require positive-pressure ventilation. Justrite cabinets offer fire-baffle protected vents to connect to these systems.