Developing a Chemical Hygiene Plan

It is required by OSHA for any company dealing with hazardous chemicals in the workplace to develop a Chemical Hygiene Plan (CHP). The purpose of a CHP is to provide guidelines for protecting employees from health hazards associated with chemicals in the laboratory and keeping chemical exposure below the designed limits set forth by OSHA section 1910.1450(c).

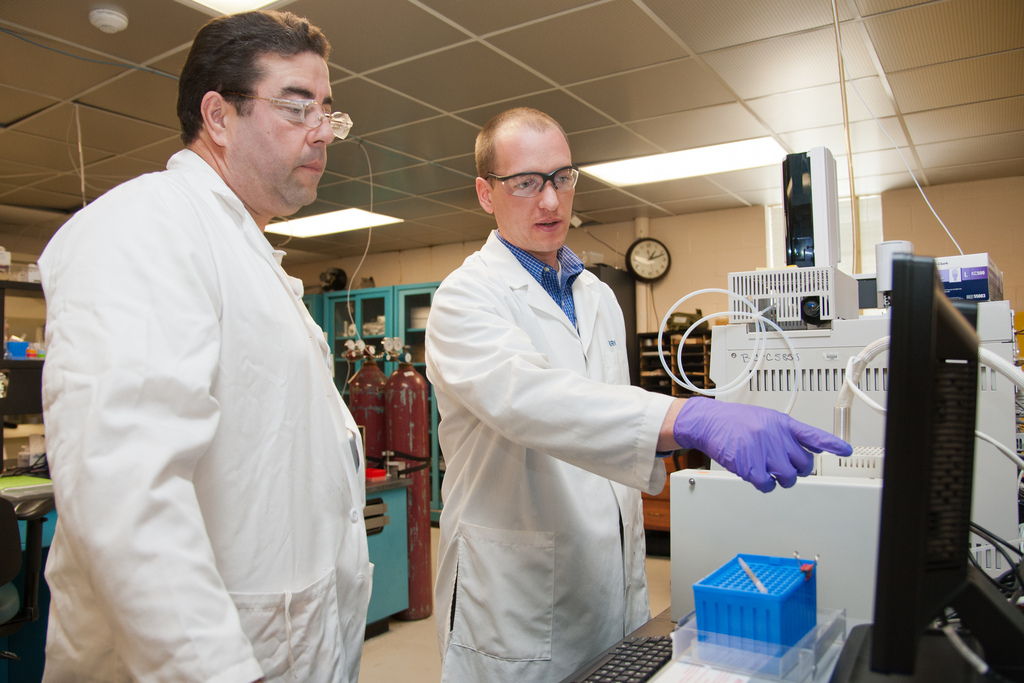

Keeping employee exposure to hazardous chemicals at a minimum can be a daunting task. Below is a basic outline of a Chemical Hygiene Plan. For official guidelines please visit OSHA.gov. Having the proper laboratory equipment and making periodic checks to ensure proper functionality is essential to maintaining a safe working environment. When working with hazardous chemicals, fume hoods and proper safety cabinets are integral to proper storage.

To keep down toxic fumes from open waste containers, always use an ECO Funnel along with the proper container and secondary containment.

The elements covered within a CHP to ensure employee safety include:

- Standard operating procedures when performing laboratory work with hazardous chemicals.

- The criteria

used to determine and implement control measures to help reduce employee

exposure to hazardous chemicals including proper PPE, hygiene practices and

engineering controls. Special attentions

should be given to any chemicals known to be extremely hazardous.

- All should be stored correctly in properly functioning fume hoods and safety cabinets. This should include specific measures to take when checking if chemical storage equipment is performing correctly and the actions to take to remedy the situation if equipment does not meet standards.

- Information and training for employees on

proper use and understanding of the chemicals being used in their workplace.

- Information and training

should be provided to the employee at the time of the initial assignment in

a work area where hazardous chemicals are present and prior to assignments

involving new exposure situations. (This

information and training should be reviewed periodically at the employers’

discretion.)

- The type of information provided to the employee includes:

- The contents and of this standard and its appendices which is available to the employee.

- Where the employee can find the CHP.

- The permissible exposure limits for OSHA regulated substances and/or recommended exposure limits for other hazardous chemicals where there is no applicable OSHA standard.

- Signs and symptoms of exposures to hazardous chemicals used in the laboratory.

- The location and availability of known reference material on the hazards, safe handling, storage and disposal of hazardous chemicals found the in laboratory including, but not limited to, safety data sheets received from the chemical supplier.

- Training of employees should include:

- Methods and observations that may be used to detect the presence or release of a hazardous chemical.

- The physical and health hazards of chemicals in the work area.

- What measures employees should take to protect themselves from these hazards. This includes procedures the employer has implemented to protect employee exposure to hazardous chemicals, appropriate workplace practices, emergency procedures and proper PPE.

- The employee should also be trained on the details of the written CHP.

- The circumstances under which a particular laboratory operation, procedure or activity shall require prior approval from the employer or employer’s designee before implementation.

- The type of information provided to the employee includes:

- Information and training

should be provided to the employee at the time of the initial assignment in

a work area where hazardous chemicals are present and prior to assignments

involving new exposure situations. (This

information and training should be reviewed periodically at the employers’

discretion.)

- Provisions

for medical consultation and medical examination.

- The employer shall provide all employees who

work with hazardous chemicals an opportunity to receive medical attention,

including any follow-up examinations which the physician determines to be

necessary under the following circumstances:

- When an employee develops signs or symptoms from exposure to a hazardous chemical used in the laboratory.

- Where exposure monitoring reveals and exposure level routinely above the action level (or PEL) for an OSHA regulated substance for which there are exposure monitoring and medical surveillance requirements, medical surveillance shall be established for the affected employee as prescribed by the particular standard.

- Whenever an event takes place in the work area such as a spill, leak, explosion or other occurrence resulting in the likelihood of a hazardous exposure, the affected employee shall be provided the opportunity for a medical consultation. This consultation will determine the need for a medical examination.

- All medical examination and consultations must be performed by or under the direct supervision of a licensed physician and shall be provided without cost to the employee, without loss of pay and at a reasonable time and place.

- Information

provided to the physician(

by the employer):

- Identify the hazardous chemical to which the employee may have been exposed.

- Description of the conditions under which the exposure occurred including quantitative exposure data.

- Description of the signs and symptoms of exposure that the employee is experiencing, if any.

- Physicians

written opinion

- The employer shall obtain a written opinion

from the examining physician which will include the following:

- Any recommendation for further medical follow-up

- The results of the medical examination and any associated tests

- Any medical condition which may be revealed in the course of the examination which may place the employee at increased risk as a result of exposure to a hazardous workplace.

- A statement that the employee has been informed by the physician on the results of the consultation or medical examination and any medical condition that may require further examination or treatment.

- The written opinion shall not reveal specific

findings of diagnoses unrelated to occupational exposure

.

.

- The employer shall obtain a written opinion

from the examining physician which will include the following:

- The employer shall provide all employees who

work with hazardous chemicals an opportunity to receive medical attention,

including any follow-up examinations which the physician determines to be

necessary under the following circumstances:

- Designation of personnel responsible for implementation of the CHP including the assignment of a Chemical Hygiene Officer, or when appropriate, establishment of a Chemical Hygiene Committee

- Provisions

for additional employee protection for work with particularly hazardous

substances. These include “select

carcinogens,” reproductive toxins and substances which have a high degree of

acute toxicity. Specific consideration

shall be given to the following provisions which shall be included where

appropriate:

- Establishment of a designated area.

- Use of containment devices such as fume hoods or glove boxes.

- Procedures for safe removal of contaminated waste

- Decontamination procedures

- The employer shall review and evaluate the effectiveness of the CHP at least annually and update it as necessary.

This information is in reference to the information set forth by OSHA and can be viewed in its entirety as standard number 1910.1450, Occupational exposure to hazardous chemicals in laboratories. All regulations should be viewed through the official source; the above should be used as an unofficial reference to the guidelines set forth by OSHA.

Recent Posts

-

Disinfecting Surfaces in the Era of Covid and EPA Registered Commercial Disinfectants and Viricides

The disinfection of surfaces at home, in public spaces, and in hospitals and clinics needs to be a …15th Jan 2023 -

Working with Inorganic Acids in the Laboratory: A Practical Guide

Working with Inorganic Acids in the LaboratoryAcids are of great importance in the laboratory and ar …4th Jan 2023 -

The Top 12 Drinking Water Contaminants

1.Lead- from older plumbing systems pre-1986, when lead pipes, solder, and components were banned. …14th Dec 2022